Modern solutions from Bsign: how to make durable and enduring custom signs

Signs in the interior of your business space are more than just navigation. They are part of the company's image, an indicator of style and taste and the elements of aesthetic appeal.

However, even a modern design can be spoiled by poor quality of the materials. Further we will disclose how to avoid ruining the first impression of the client and not to "burn out" on the details.

High-quality materials are the guarantee of durability for custom business signs

The experience of Bsign company in the production of modern durable signs is more than 10 years. During this time, we have established the golden rule: the production of a quality product begins with selecting reliable and suitable materials. Therefore, we purchase the best raw materials only from proven manufacturers who guarantee a long service life of their products in all weather conditions.

For the manufacture of signs, we use:

- Acrylic. It is a durable and strong material, resistant to mechanical damage and environmental influences such as extreme temperatures or high moisture. However, acrylic is quite plastic, so it is easy to be processed, form different shapes from it and create various sophisticated designs and long-lasting acrylic signs.

- Wood — a material created by nature. At Bsign, we use 6 types of this raw material for maintaining wood signs, which are distinguished by strength and endurance even in harsh weather conditions. However, this wood undergoes additional processing so that the product does not deform over time and does not lose its attractive look.

- Stainless steel — a quality material which is resistant to corrosion. Steel does not change its original appearance for decades, which makes it an ideal raw material for the manufacture of stainless steel signs.

Production technology that extends the service life and designs durable signs

The second component in the manufacture of a durable product is the production technology. To provide high quality of modern signs, we use:

- state-of-the-art material handling equipment;

- layering technology;

- manual painting and assembly.

Additionally, in the production of Bsign, every detail of the future sign is cut on a laser machine. Due to the high accuracy and effectiveness of the laser beam, both large and small and complex parts are made of acrylic, wood and even steel.

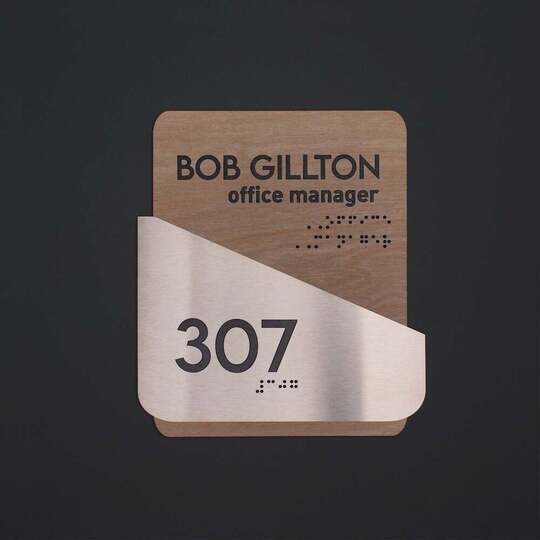

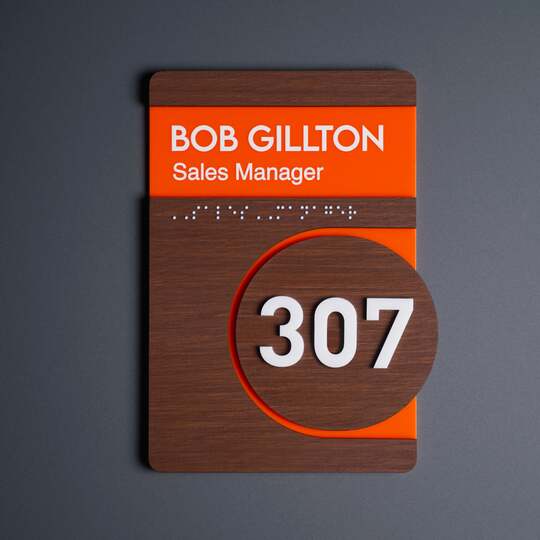

The modern layering technology allows combining several different materials in one sign. Parts made from different raw materials can be combined, layered or fixed side by side.

Inscriptions, icons, color images and tactile fonts on custom business signs are printed on a special printer.

Each stage of production is controlled to correspond to its cost effectiveness, and the resulting parts are subject to mandatory inspection before creating a complete sign.

We pay special attention to manual work when maintaining the signs. The wooden parts of our signs and signboards are sanded and painted manually. Our qualified craftsmen are also responsible for the assembly, not the machines. Due to this, we can guarantee for customers an excellent outcome of the finished product.

Materials for signs to provide resistance to external factors

Signs and signboards are used not only in the interior, but also in the exterior like wood address signs or house number signs. But wherever you place our products, they will be affected by the external environment and have to withstand harsh weather conditions. Therefore, we treat wood with special means to protect it from ultraviolet rays and moisture. Materials such as acrylic and steel are resistant to any damage without additional processing. However, to increase the durability of parts made from that raw materials, we use only weather resistant materials and apply a suitable protective coating on them.

Ergonomic design of modern signs

At first glance it seems that design has nothing to do with endurance and durability. But it’s not like that. It plays a crucial role. All the designs of our signs are thought out in terms of ergonomics. The range of sizes and shapes, the combination of selecting materials and elements, as well as every detail of the sign work for convenient placement, easy perception, clear navigation and aesthetic appearance. An example of this approach can be our Wave signs.

Conclusion

When choosing the best signs for the interior of the premises or outdoor signage, remember that quality = durability. That’s an ideal choice. Therefore, a professional product is created of reliable and proven materials, the latest technology, thorough verification of results, ergonomic and stylish design to become a smart investment.

Do you want to highlight the status with original details and attract potential customers? Are you eager to demonstrate professionalism with an exclusive style to make a lasting impression? Our specialists know which sign variant to choose for your business. Don't hesitate! Get a free consultation right today.